Login

Please enter user name and password.

Did you forget your user name or your password?

Register

You do not have an account at Cloos? Then register now.Register now

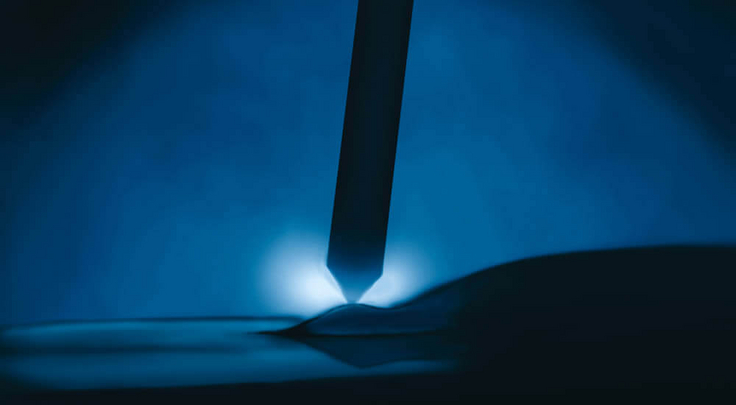

Control Weld - Through thick and thin

The Control Weld process covers the whole range of controlled MIG/MAG welding and is suitable for different applications. The classic MIG/MAG process offers a stable metal transfer from short arc to spray arc. At low power a short arc forms which is particularly advantageous when joining thin components and out-of-position welds. With regard to spray arc, this process has more energy and there is more heat input in the base material. There are only few spatters due to the small, short-circuit proof metal transfer which also results in less rework. Do you look for a reliable entry process for perfect welding quality? Then rely on Control Weld by CLOOS!

Your contact person

Mr. Jan Pitzer

Tel.: +49 2773 85-416

Click here to find suitable solutions

View solutionsThese processes could interest you

Combination of two MIG/MAG arcs for maximum deposition rate

Focused high-capacity MIG/MAG spray arc for deep penetration and efficient welding

Directionally stable MIG/MAG AC pulsed arc for optimum results when welding demanding materials

Combination of laser welding and MIG/MAG arc for maximum efficiency and quality