Login

Please enter user name and password.

Did you forget your user name or your password?

Register

You do not have an account at Cloos? Then register now.Register now

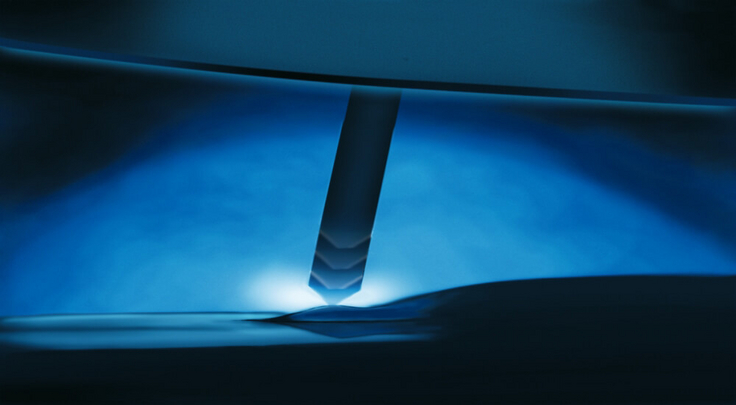

MoTion Control Weld - For fine plates and additive production

MoTion Control Weld is particularly suitable for fine plate applications and applications in the lowest capacity ranges. The welding process provides advantages everywhere where special demands to weld surface and appearance are made. MoTion Control Weld is a combination of the proven CLOOS Control Weld process and reversing wire. In the process, the wire is drawn back and forward at a frequency of up to 180 Hz which results in an extremely high process stability to the lowest capacity range. You avoid extensive reworks due to the minimised formation of spatters and powder residues. Due to these characteristics MoTion Weld is particularly suitable for applications in the additive production. Do you look for a stable process for excellent welds in fine-plate application or for additive applications? Then rely on MoTion Control Weld by CLOOS!

These processes could interest you

Combination of two MIG/MAG arcs for maximum deposition rate

Focused high-capacity MIG/MAG spray arc for deep penetration and efficient welding

Directionally stable MIG/MAG AC pulsed arc for optimum results when welding demanding materials

Combination of laser welding and MIG/MAG arc for maximum efficiency and quality